Description

IPX 2000 UHMW provided by Plastic Machining Company is a machinable advanced engineer polyethylene compound manufactured to retain the high qualities of traditional UHMW but with increased abrasion resistance and UV stability. IPX 2000 advanced wear technology is UV stabilized for long-term exposure in outdoor applications, which increases product life as well as performance. IPX allows for closer part tolerances and a high resistance to corrosive chemicals (with the exception of oxidizing acids), low moisture absorption and displays a high resistance to friction.

Due to a specialized self-lubricating formula, the coefficient of friction of IPX 2000 is significantly lower versus traditional UHMW, nylon and acetal. The additives in IPX allow for added slip; as much as 30% more for increased part life.

IPX advanced wear technology UHMW improved from 16 to 7 compared to standard UHMW in a standard slurry test. This lower number indicates as much as a 40% increase in wear resistance over competitors grades of UHMW.

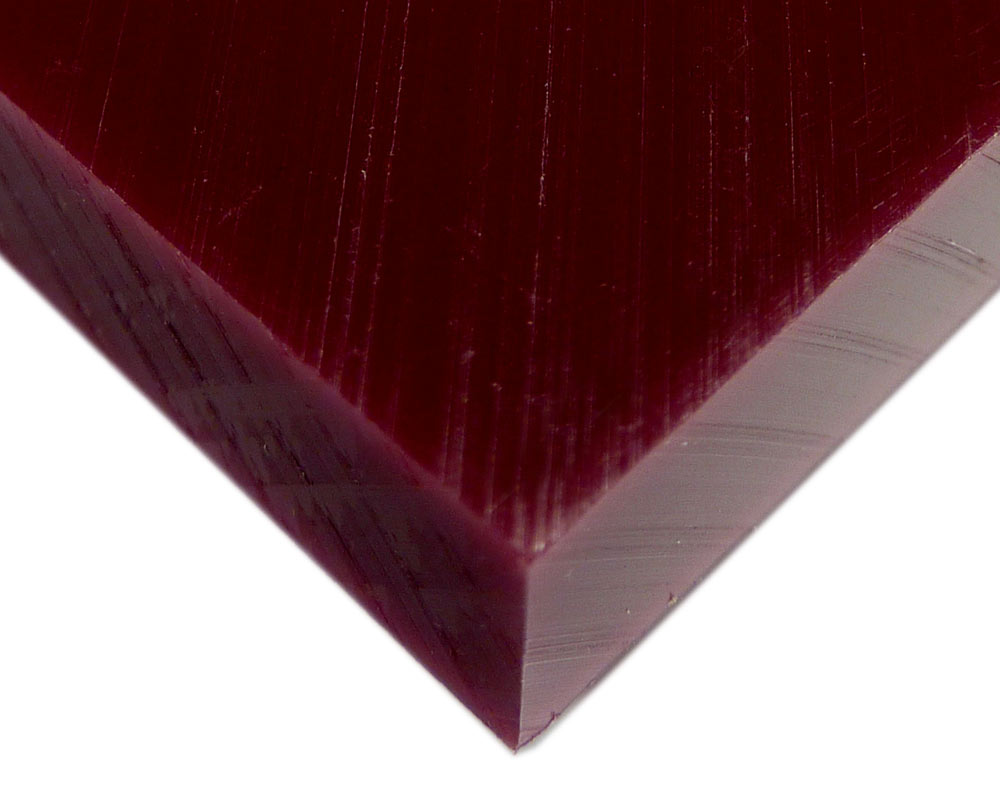

IPX 2000 is burgundy red in color and not approved for FDA contact. IPX 2000 is commonly used to improve performance in existing plastic applications and replace metals in more demanding solutions.