Industrial wastewater treatment equipment is not confined to one industry, but rather sees widespread use in a variety of commercial and industrial applications affecting nearly all consumers on a daily basis.

Wastewater industries and applications include agricultural waste and anaerobic digestion, municipal sewage and facilities management, biogas and Membrane Bioreactors (MBRs), recycling and destruction, food waste, septage, grease receiving and sludge processing to name a few.

Plastic Machining Company provides solutions to industries utilizing wastewater equipment through both low friction liners, sidehill screens and other parabolic screens as well as wear and power transmission parts for pumping stations, conveyors, headworks, compactors, sewage grinders, sludge thickeners, auger presses, dewatering machinery and other process equipment.

Plastics including fully recyclable UHMW, oil-filled high-performance nylon, and close tolerance acetal provide plastic wastewater treatment components that exhibit higher impact and abrasion resistant properties than most engineered polymers.

With extremely high wear and chemical resistance, a low coefficient of friction and zero water absorption, PMC water treatment components are designed to excel when submerged in the harshest sludge and contaminated water environments.

Sprockets, bearings, wear shoes and waste water treatment parts are manufactured in Plastic Machining Company’s own facilities from high performance, industrial grade engineered polymers. Three decades of exceptional service continues to make Plastic Machining a leader in high-performance water treatment and corrosion resistant wear products.

Common Wastewater & Water Treatment Industry Components:

- H78 drive sprockets

- Jaw clutch with hand wheels

- Trip cam sprockets

- Shear pin sprockets

- Stainless steel hubs with replaceable UHMW teeth

- H78 combination split dish sprockets

- 720/715 flight sprockets

- Chain tensioners

- Return and carrying wear shoes

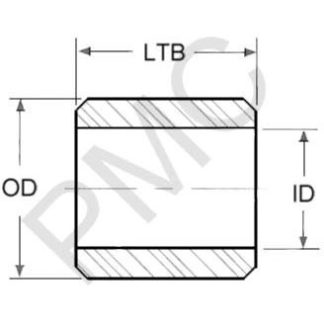

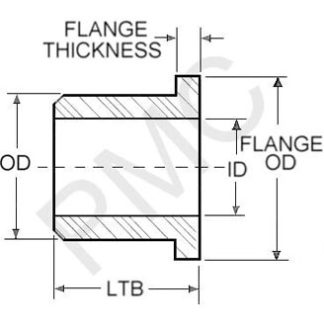

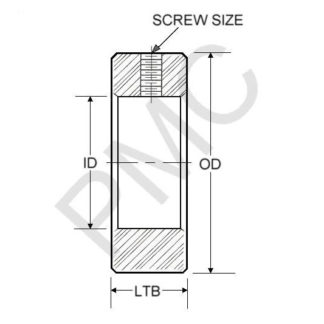

- Split static bushings

- Split shaft collars

- Wear strips

- Weld washers

Features & Benefits:

- Available in food grade and NSF compliant materials

- Self lubricating

- Abrasion, corrosion, impact and moisture resistant

- Low coefficient of friction

- Completely inert to most corrosive chemicals

- Won’t rust or seize

- Handles a full working load of corresponding chain

- Reduced down time and maintenance costs

- Reduced power consumption

- Extended component wear-life

- Noise reduction

- Quick and easy installation