PEEK plastic machining performed by Plastic Machining Company focuses on wear parts and power transmission components, generally in high heat applications. While UHMW, nylon, and acetal are the most utilized plastics for a wide variety of these applications, PEEK plastic offers additional benefits for specifically demanding applications, especially in corrosive and hot environments.

Popular for high heat bushings and washers, PEEK plastic is a temperature-resistant semi-crystalline engineered machinable thermoplastic with excellent chemical resistance, fatigue resistance, and thermal stability. PEEK exhibits superior mechanical and electrical properties with a maximum continuous working temperature of 480°F to 500°F and excellent retention of mechanical properties up to 570°F in a steam or high-pressure water environment.

Popular for high heat bushings and washers, PEEK plastic is a temperature-resistant semi-crystalline engineered machinable thermoplastic with excellent chemical resistance, fatigue resistance, and thermal stability. PEEK exhibits superior mechanical and electrical properties with a maximum continuous working temperature of 480°F to 500°F and excellent retention of mechanical properties up to 570°F in a steam or high-pressure water environment.

PEEK excels in low-temperature environments as well, many times utilized in Arctic equipment; for example both bearings and valve seals in Arctic wind turbines. PEEK is, however, more brittle versus PTFE at these extremely low temperatures. In gas and steam industrial turbines, PEEK bushings reduce rotational friction and vibration, supporting loads able to turn at higher speeds without degradation and stand up to steam, hot water and the vast majority of corrosive chemicals.

We effectively utilize PEEK as a metal/stainless steel replacement in these harsh environments for weld washers, thrust washers, sleeve bushings and flange bushings, among others. Even as a premium material, PEEK has a proven track record of reliably replacing specialty metals and materials that can cost up to ten times as much to service for same machinery or application and with a weight savings of up to 70% versus aluminum parts.

PEEK’s often pays for itself with these weight savings advantages leading to increased efficiency and longer part life. In a recent trial, PEEK manufacturer Victrex™ claimed it saw a 9% increase in efficiency within automotive manufacturing conveying systems that utilized PEEK bearings. The facility also noticed a 3-decibel decrease in noise levels, easily noticeable to the human ear and increasing worker safety. Other applications range from large seals in hydraulic and pneumatic equipment systems to tiny hand-help high heat tweezers.

Plastic Machining Company’s master machinists and state-of-the-art CNC lathe machinery produce exceptional results for materials used for food processing, corrosion resistant, and high wear applications.

PEEK vs. UHMW & Nylon

PEEK has an extremely low coefficient of thermal expansion and experiences negligible thermal deformation at high operating temperatures. PEEK’s “K-factor” or resistance to wear, is between that of UHMW and bearing grade nylon, slightly more resistant to wear than UHMW. PEEK has a limiting PV value much higher than both UHMW and nylon.

While PEEK does not have the lowest coefficient of dynamic friction, nor the lowest K factor of machinable plastics, it offers a high limiting PV coupled with outstanding thermal stability, making it suitable for high-performance bushings, bearings, and washers.

Plastic Machining Company’s most popular PEEK components include:

- Weld Washers

- Thrust Washers

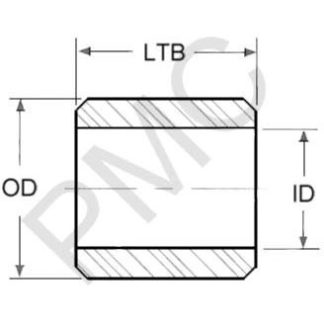

- Sleeve Bushings

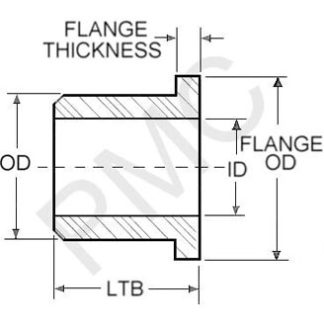

- Flange Bushings

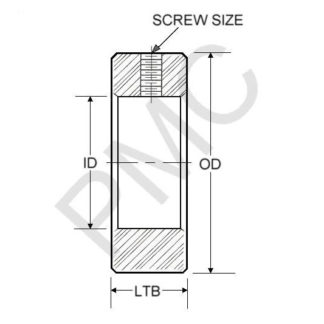

- High-Speed Bearings

- “O” Rings and Seals

-

PEEK High-Heat Unfilled Virgin Rod

In stock

Read more -

PEEK High-Heat Unfilled Virgin Sheet

$2,512.32 – $19,429.20In stock

Select options This product has multiple variants. The options may be chosen on the product page