Plastic Machining Company uses high-quality UHMW, nylon, and acetal plastic sheet, rod and tube from manufacturers including Quadrant Engineering Plastics, Cast Nylons, Ensinger, Rochling and other resin converters.

The same high-quality materials we use for our components may be purchased as semi-finished plastic sheet, rod and tube. See our selection below; standard sheet size and rod/tube length depend on the material and material grade.

The same high-quality materials we use for our components may be purchased as semi-finished plastic sheet, rod and tube. See our selection below; standard sheet size and rod/tube length depend on the material and material grade.

Comparing nylon, UHMW & acetal: Both nylon and UHMW plastics feature low friction, self-lubricating grades and long life in high wear applications.

Nylon comes in FDA compliant grades for food processing machinery and has a higher tensile strength as well as a higher ratio of stress to strain in flexural deformation.

UHMW features higher impact strength with more resistance to chemicals. It also has high abrasion resistance and near-zero water absorption.

Copolymer acetal and homopolymer Delrin® offer low moisture absorption (not quite as much as UHMW) and desirable chemical resistance. In addition, it has higher mechanical strength, rigidity and dimensional stability (change resulting from exposure to varying temperature).

Dimensional stability is a consideration in strict tolerance part applications where little to no expansion of the material is required. Acetal / Delrin is stronger than both UHMW and nylon plastics.

UHMW plastic, nylon plastic, and acetal / Delrin plastic all carry the advantage of resisting moisture, with near zero water absorption, while also resisting harsh chemicals and contaminants. Plastic power transmission parts do not rust like many metals and survive in the harshest of environmental conditions.

-

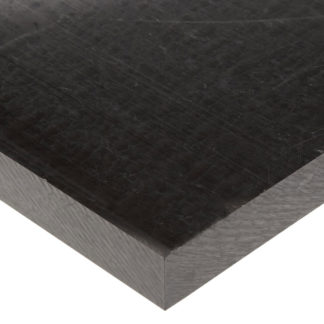

Delrin® – High Strength Black Homopolymer Acetal Sheet

$449.09 – $1,593.14In stock

Select options This product has multiple variants. The options may be chosen on the product page -

IPX® Advanced Wear Technology UHMW Sheet

$506.14 – $2,962.13In stock

Select options This product has multiple variants. The options may be chosen on the product page -

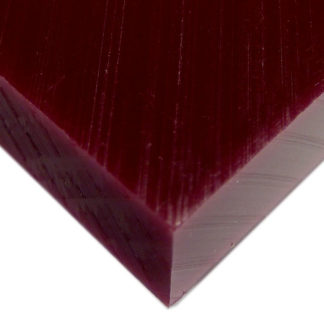

Nylatron® GS PA66 – MoS2 Filled Nylon Sheet

$97.10 – $3,203.52In stock

Select options This product has multiple variants. The options may be chosen on the product page -

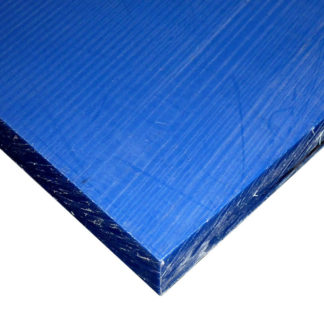

Nylatron® GSM PA6 – Blue Bearing Grade Nylon Sheet

$4,158.02 – $13,904.76In stock

Select options This product has multiple variants. The options may be chosen on the product page -

Nylatron® GSM PA6 – Blue Bearing Grade Nylon Tube

$135.46 – $492.50In stock

Select options This product has multiple variants. The options may be chosen on the product page -

Nylatron® NSM – Bearing Grade Nylon Rod

$432.74 – $2,181.32In stock

Select options This product has multiple variants. The options may be chosen on the product page -

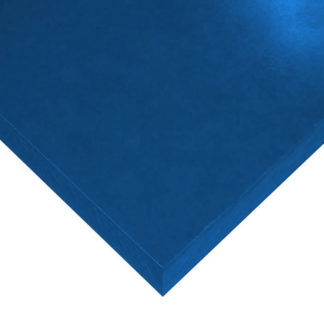

Nylatron® NSM – Bearing Grade Nylon Sheet

$1,001.80 – $2,897.95In stock

Select options This product has multiple variants. The options may be chosen on the product page -

Nyloil® – Oil-Filled Bearing Grade Nylon Rod

$156.28 – $581.59In stock

Select options This product has multiple variants. The options may be chosen on the product page -

Outrigger Pads – High Performance Heavy Duty UHMW Jack Pads

$0.00Call 877-239-4338 for pricing.

Select options This product has multiple variants. The options may be chosen on the product page -

PEEK High-Heat Unfilled Virgin Rod

In stock

Read more -

PEEK High-Heat Unfilled Virgin Sheet

$2,512.32 – $19,429.20In stock

Select options This product has multiple variants. The options may be chosen on the product page -

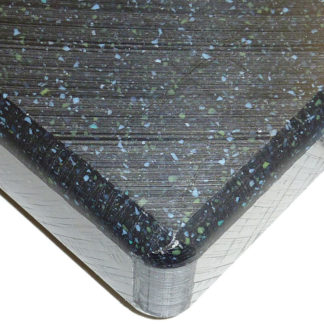

Tivar 88® – Premium Lining & Bulk Material Handling UHMW Sheet

$831.71 – $6,653.82In stock

Select options This product has multiple variants. The options may be chosen on the product page