Plastic Machining Company (PMC) is a leader in OEM, power transmission and custom plastic parts for the replacement of metal components used in paper mill and packaging machines.

PMC provides a myriad of paper and paper packaging applications: for pulpers, chip sizing screens, flat back elbow liners, under chain wear plates, wood chip drag conveyor flights and other paper mill machines, PMC offers Tivar® PolySteel. PolySteel is a magnetically detectable grade of UHMW plastic that can be easily separated from a wood pulp solution. This eliminates potential problems from more brittle materials that may leave small filings or chips that contaminate paper pulp.

PMC provides a myriad of paper and paper packaging applications: for pulpers, chip sizing screens, flat back elbow liners, under chain wear plates, wood chip drag conveyor flights and other paper mill machines, PMC offers Tivar® PolySteel. PolySteel is a magnetically detectable grade of UHMW plastic that can be easily separated from a wood pulp solution. This eliminates potential problems from more brittle materials that may leave small filings or chips that contaminate paper pulp.

Equipment found in paper mills often operate in wet or high moisture environments. Examples include conveyor lines, screens, pulp agitators, formers, presses, dryers, reels, and fluid systems. Additionally, many paper types require additives and coatings applied through a steam shower or spray dampener system. PMC provides UHMW, acetal, and many alternative plastics with high moisture resistance and near-zero water absorption. Many that resist corrosion from chemicals and protect parts used in the manufacturing process with the additional benefits of cost savings and weight advantages over metal counterparts.

In packaging conveyor systems, PMC utilizes durable nylon, UHMW, acetal, Delrin and other low friction materials to increase dewatering efficiency while keeping the properties of the paper intact and consistent.

Plastic wear parts and guides that feature low friction lead to damage free boxes, bags, rolls, and sensitive packaging materials. Replacing costly metallic parts with plastic equivalents will save money by reducing damaged runs and creating longer intervals between replacing parts.

Benefits of Plastics for Paper and Paper Packaging Applications

Benefits of Plastics for Paper and Paper Packaging Applications

- “Pulp-safe” grades available

- Increased dewatering efficiency

- Reduced damaged runs on packaging materials

- Increased part life for conveyor, pulp, and other paper mill machines

- High moisture and corrosion resistance

- Direct replacement of OEM parts (identical part designs)

- Cost effective/reduced costs over stainless steel

- Lightweight (15% the weight of steel)

Popular Products for Paper and Paper Packaging Applications

- Power Transmission Components

- Custom manufacturing/machining

- Plastic replacement components for OEM equipment and metal components

- Conveyor Tracks & Chain Guides and Wear Strips for reduced damaged runs

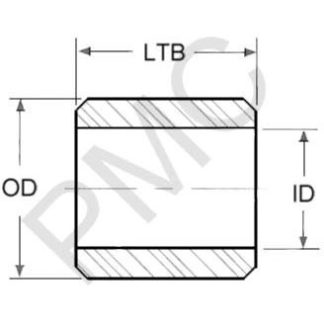

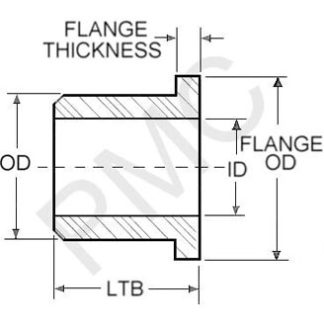

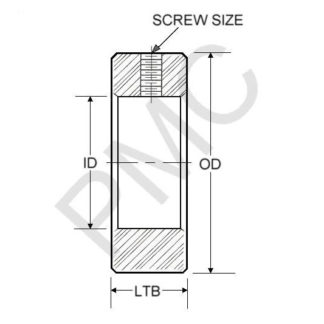

- Bushings & Washers and Bearings & Inserts for wet/high-moisture environments

- Roller Chains, Pulleys & Rollers, and Sprockets for conveying systems