Plastic Machining Company replaces metal power transmission parts in commercial and industrial equipment and systems, with direct replacement plastic parts that offer the same abilities as their metal counterparts.

Our power transmission parts exhibit desirable benefits including cost savings, increased wear and part life, high corrosion and moisture resistance, a versatile temperature range, increased reliability, and superior sound deadening.

Power transmission is the use of gears, pulleys, sprockets and other power transmission parts to harness control over the application of power in a mechanical system. Mechanical power may be transmitted through power transmission parts to adjust the amount of torque or force vs. speed output by the system.

While ubiquitous and found in nearly every industry, Plastic Machining Company has extensive experience in replacement parts for OEM equipment in:

- Conveying systems

- Food and beverage processing

- Wastewater treatment

- Lumber industries

- Bottling and canning

- Construction and architecture

- Commercial hygienic equipment (e.g. toxic material handling)

- Agriculture

- Appliances and automation

- Hydraulics & fluid power

- Industrial motors & controls

While most parts in the past have been made from various metals, plastic power transmission technology has come a long way in the past decade, with new plastic technologies providing a plethora of grades with desirable properties that push the previous limits of load-bearing, torque handling, and gear drive capacities.

Here are some of our most popular machined wear and power transmission categories:

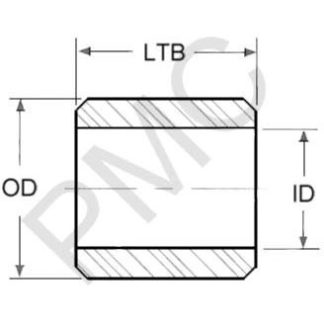

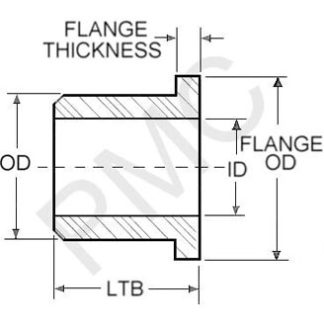

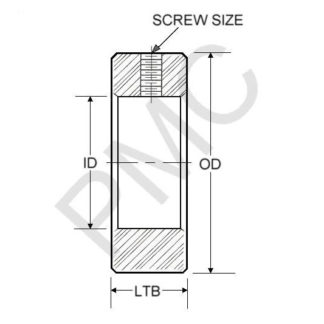

- Bushings & Washers (Nylon)

- Bearings & Inserts (Nylon, UHMW)

- Collars & Shaft Collars (Acetal / Delrin)

- Gears & Gear Racks (Nylon, Acetal / Delrin)

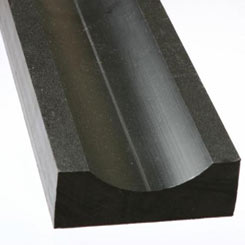

- Guides (UHMW)

- Roller Chains (Nylon, Acetal / Delrin, Polypropylene)

- Pulleys & Rollers (UHMW)

- Sprockets (Nylon, UHMW)

- Tracks & Chain Guides (UHMW)

- Wear Parts & Wear Strips (Nylon, UHMW)

We also carry a full line of PolyHi-Solidur replacement parts. We can create custom parts or modify existing parts. Send us a quote request today!

Power transmission parts from Plastic Machining Company provide benefits that simply cannot be matched by its metal counterparts. In recent years, the use of plastic power transmission parts has expanded from mostly lower loads to higher demanding load applications.

Machined and molded power transmission parts made from these high-performance plastics offer long life, quieter transmission of power, self-lubrication, and the ability to create systems that with fewer parts leading to savings and ease of maintenance.

UHMW and acetal/Delrin carry the advantage of resisting moisture, with near zero water absorption, while also resisting harsh chemicals and contaminants. PMC parts do not rust like many metals and survive in the harshest of environmental conditions.