UHMW plastic features a combination of low friction, strong toughness and high chemical resistance, ideal for reducing friction, wear, energy consumption and noise levels in countless industrial and commercial applications. These properties increase equipment and part life and efficiency, lowering costs that many times pay for the replacement parts over the life of the material.

UHMW plastic features a combination of low friction, strong toughness and high chemical resistance, ideal for reducing friction, wear, energy consumption and noise levels in countless industrial and commercial applications. These properties increase equipment and part life and efficiency, lowering costs that many times pay for the replacement parts over the life of the material.

Highly durable and inherently self-lubricating, UHMW’s molecular weight provides high impact strength and abrasion resistance.

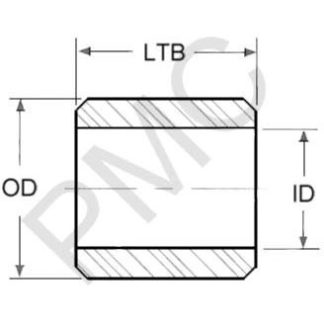

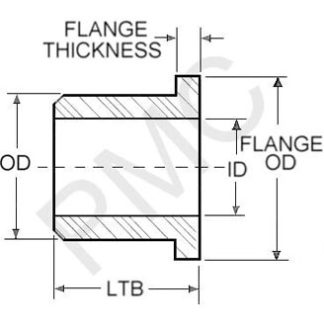

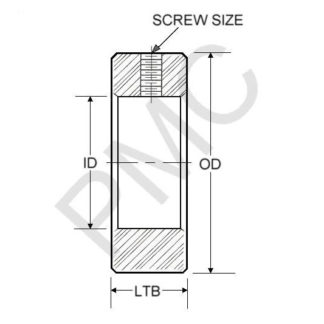

UHMW is easy to machine and fabricate with woodworking and shop tools and outperforms metal in many applications. UHMW can be machined into virtually anything from small gears and bearings to huge sprockets.

In comparison to nylon plastic, UHMW features higher impact strength with more resistance to chemicals. It also has high abrasion resistance and near-zero water absorption.

Reprocessed grades, enhanced bearing and wear grades and FDA compliant grades are available for greatly extended part life. Plastic Machining Company provides specialized grades of UHMW to enhance particular features to suit a wide range of applications. UHMW plastic can operate in temperatures up to 180F and with specialty grades that can enhance the temperature range to 300F. UHMW also performs at extremely low temperatures without degradation or becoming brittle.

UHMW Plastic Features

- Fabricates and machines easily with common woodworking and shop tools

- Heat weldable

- Highly resistant to most chemicals

- Near-zero moisture absorption

- Extremely low coefficient of friction

- Self-lubricating

- Highly resistant to wear and abrasion

- Extends equipment life

- Reduced maintenance costs and energy consumption

Give us a call today for help finding the UHMW plastic grade best suited for your application!

-

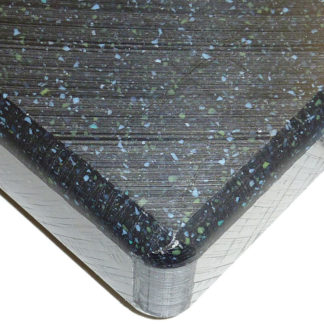

IPX® Advanced Wear Technology UHMW Sheet

$506.14 – $2,962.13In stock

Select options This product has multiple variants. The options may be chosen on the product page -

Outrigger Pads – High Performance Heavy Duty UHMW Jack Pads

$0.00Call 877-239-4338 for pricing.

Select options This product has multiple variants. The options may be chosen on the product page -

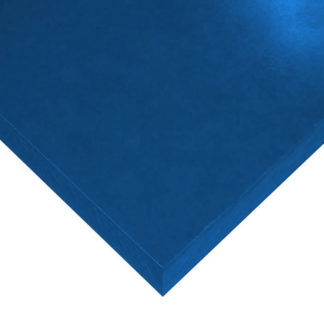

Tivar 88® – Premium Lining & Bulk Material Handling UHMW Sheet

$831.71 – $6,653.82In stock

Select options This product has multiple variants. The options may be chosen on the product page -

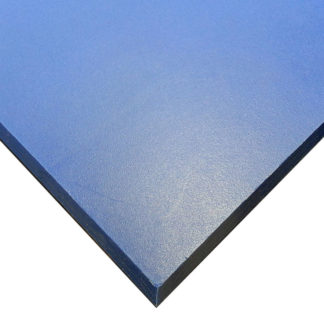

Tivar® H.O.T. – Extended Range High-Heat UHMW Sheet

$437.64 – $5,251.43In stock

Select options This product has multiple variants. The options may be chosen on the product page -

Tivar® HPV – Bearing Grade Ultra-Low Friction UHMW Sheet

$722.07 – $3,282.03In stock

Select options This product has multiple variants. The options may be chosen on the product page