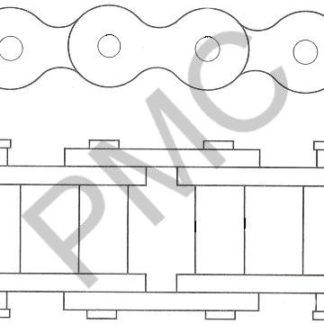

Plastic Machining Company offers roller chains in nylon, acetal, Delrin®, and polypropylene.

Most plastic roller chains can be used with steel or plastic sprockets, work under a wide range of speeds and loads. Plastic chain and drive components excel in harsh chemical, high-moisture, and high-heat environments.

Oil-filled nylon features self-lubrication, ideal for food processing machinery. Nylon has a low coefficient of friction as well as desirable abrasion and chemical resistance. Nylon is a rigid material, which resists creep and distortion of sprocket key-ways under high loads. Sprockets made from oil-filled nylon include those used with roller chain and flat top chain.

Oil-filled nylon features self-lubrication, ideal for food processing machinery. Nylon has a low coefficient of friction as well as desirable abrasion and chemical resistance. Nylon is a rigid material, which resists creep and distortion of sprocket key-ways under high loads. Sprockets made from oil-filled nylon include those used with roller chain and flat top chain.

Although somewhat brittle, acetal (also known as Delrin®), offers incredibly close tolerances and resists creep. It has a low coefficient of friction and a fair but lower abrasion resistance versus other roller chain plastics.

Polypropylene is designed for lower load applications but offers a balance of thermal, chemical, and electrical specs. Polypropylene features a low coefficient of friction and fair impact and abrasion resistance for its cost effective price.

Plastic Machining Company has the expertise to guide you in choosing the right material for your application.

-

Roller Chains – Acetal Light Duty Chain

$0.00 Select options This product has multiple variants. The options may be chosen on the product page -

Roller Chains – Nylon Light Duty Chain

$0.00 Select options This product has multiple variants. The options may be chosen on the product page -

Roller Chains – Polypropylene Light Duty Chain

$0.00 Select options This product has multiple variants. The options may be chosen on the product page