Plastic Machining Company today showcased its parts and precision custom machining services for water treatment industries ahead of WEFTEC (Annual Environment Technical Exhibition and Conference) 2017, the largest water and waste water treatment technology conference in the U.S.

Plastic Machining Company provides advanced plastic technology solutions to industries utilizing waste water equipment through OEM and custom parts including low friction liners, sidehill screens and other parabolic screens as well as wear and power transmission parts for pumping stations, conveyors, headworks, compactors, sewage grinders, sludge thickeners, auger presses, dewatering machinery and other process equipment.

At the headworks of a treatment plant, screens are used in high-performance systems that provide a high capture rate of waste water solids, resulting in a discharge that is remarkably clean and ready for disposal. When unwanted solids are removed at the headworks of a treatment plant, it allows for a more reliable operation for the entire facility.

Many high-flow waste water screens, both fine and coarse, feature UHMW perforated plates instead of traditional stainless steel. UHMW offers a more effective means to capture, remove and clean waste water debris.

Plastics including fully recyclable UHMW, oil-filled nylon and close tolerance acetal have become proven, effective materials for waste water treatment components, exhibiting higher impact and abrasion resistant properties than most engineered polymers.

With extremely high wear and chemical resistance, a low coefficient of friction and zero water absorption, PMC water treatment components are designed to excel when submerged in the harshest sludge and contaminated water environments.

Industrial waste water treatment equipment is not confined to one industry, having widespread use in a variety of commercial and industrial applications affecting nearly all consumers daily.

These industries and applications include agricultural waste and anaerobic digestion, municipal sewage and facilities management, biogas and Membrane Bioreactors (MBRs), recycling and destruction, food waste, septage, grease receiving and sludge processing among others.

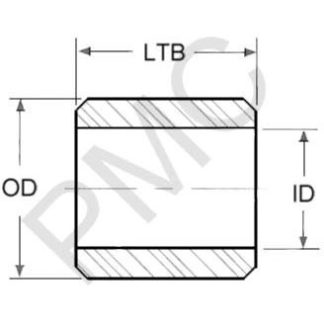

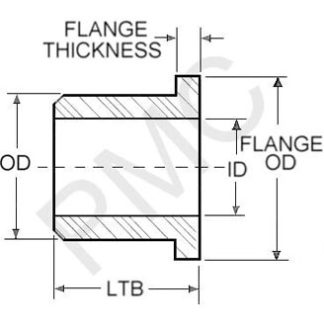

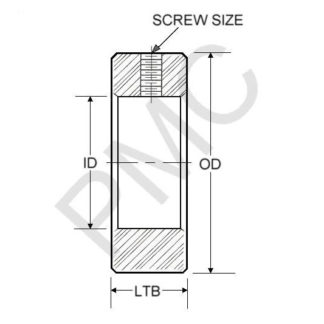

Sprockets, bearings, wear shoes and other parts for waste water systems and waste water treatment parts are manufactured in Plastic Machining Company’s own facilities from high performance, industrial grade engineered polymers. Three decades of exceptional service continues to make Plastic Machining a leader in high-performance water treatment and corrosion resistant wear products.

Plastic Machining Company (PMC) provides industry leading plastic machining, semi-finished sheet and rod, custom-designed and OEM parts, as well as plastic replacements for metal power transmission components. PMC plastic sheet, rod, and parts are crafted from high-performance materials from Quadrant, Cast Nylons, Ensinger, Poly-Hi Solidur and other resin converters, manufactured with precision state-of-the-art CNC routers, mills, and lathes. PMC parts scale from over twenty feet long and ten inches thick to parts that can rest on the tip of a finger. PMC can produce most custom parts within fifteen working days. Contact a PMC representative for specifics. Call 877-239-4338 or visit www.plasticmachiningcompany.com.