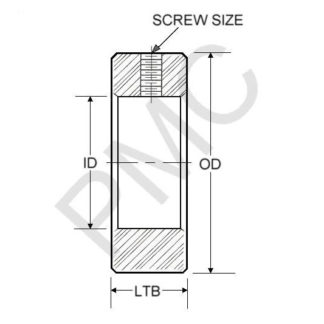

Aerospace industries have witnessed a drastic increase over the last decade in plastic components used for aviation, spaceflight, and satellite applications. New plastics and plastic technologies are pushing the previous limitations of load-bearing, torque handling, and gear drive capabilities of plastic aerospace parts. Specialty plastics including PEEK, PPS, and acrylic-polyvinyl chloride (Kydex®) offer superior heat, chemical and radiation resistances allow plastics to play a significant role in aerospace and featuring many of same desired traits as traditionally used metals: low friction and high strength, high dimensional stability, as well as resistance to heat, impact, and corrosion. Fillers and additives in plastic resins, such as glass or lubricating oils, enhance characteristics specific to an application’s requirements. Heat resistant and non-corrosive plastics like PEEK can even be machined to replace metal fasteners and screws with no needed change in the overall design of the original part, allowing for the direct replacement of OEM components.

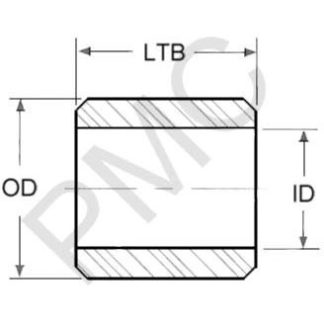

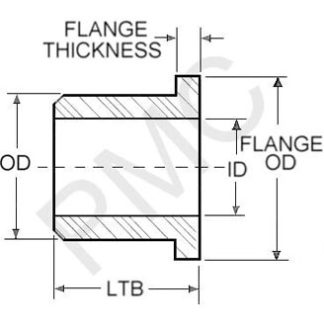

Examples of lightweight aerospace components include gaskets, seals, guides, brackets, spacers, washers and other support parts where high-heat plastics can outperform metals, providing thermal and mechanical stability, desirable insulation properties, zero flammability, low outgassing in a vacuum, and resistance to jet fuel and other chemicals.

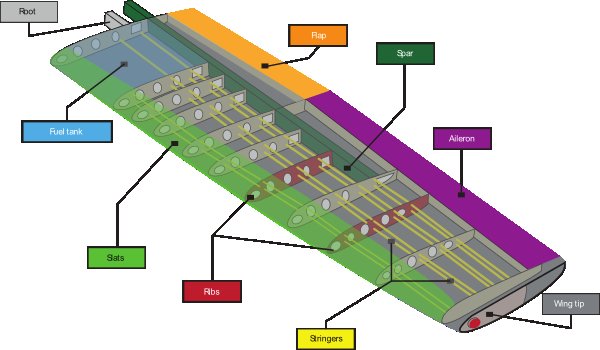

PEEK and PPS plastic first made their way into structural aerospace applications in the mid-1990’s used for ribs and spars for undercarriage doors and floor panels in small aircraft. In the 2000s, aerospace giants Airbus and Gulfstream utilized PPS in thermoplastic skins reinforced with welded ribs, finding a 20% savings in weight compared with the previously used aluminum structures. This lightweight alternative for aircraft frame support has also seen use in military aircraft; one notable advancement in military helicopter technology was Lockheed Martin’s introduction of PPS and PEEK plastics for the structural supports of the cargo area on the Sikorsky CH-53K King Stallion heavy-lift cargo helicopter. The United States military has also introduced these plastics to the structural supports of stealth aircraft, using specialty grades that absorb radar waves, reducing radar signature.

PEEK and PPS plastic first made their way into structural aerospace applications in the mid-1990’s used for ribs and spars for undercarriage doors and floor panels in small aircraft. In the 2000s, aerospace giants Airbus and Gulfstream utilized PPS in thermoplastic skins reinforced with welded ribs, finding a 20% savings in weight compared with the previously used aluminum structures. This lightweight alternative for aircraft frame support has also seen use in military aircraft; one notable advancement in military helicopter technology was Lockheed Martin’s introduction of PPS and PEEK plastics for the structural supports of the cargo area on the Sikorsky CH-53K King Stallion heavy-lift cargo helicopter. The United States military has also introduced these plastics to the structural supports of stealth aircraft, using specialty grades that absorb radar waves, reducing radar signature.

Spaceflight has also benefited from an increase in nylon and PEEK plastic use. NASA layers spacecraft structures with Kevlar with nylon plastics for protective insulation. Specialty nylon and polycarbonate plastics are found on spacesuits as well, including the outer construction of the helmet and visor. These plastics are looked to for their high thermal stability, tensile strength, and flammability resistance. UV radiation resistance is an option for many materials and sulfur polymers may be added for gamma x-ray radiation resistance. Some plastics, such as boron-filled olephins are used specifically for this purpose.

In commercial flights, one pound equates to as much as one dollar in additional fuel cost, per flight. That number jumps to around ten thousand dollars per pound for orbital spaceflights. Even small amounts of weight reduction can lead to massive cost savings over the lifetime of an aircraft, rocket or satellite.

Today, a Boeing 787 aircraft uses as many as fifteen thousand carbon-fiber filled PPS plastic cleats and clips that secure exterior skins to the aircraft frame. High performance, high heat plastics are also used to provide reinforcement between fuselage frames.

Cast acrylic plastic is used for aircraft cabin windows, fighter canopies, windscreens, wing-tip lenses, outer laminates and instrument panels for general aviation and military aircraft. Many acrylics meet the needs of the demanding aerospace industry, compliant with U.S. Military Material Specifications MIL-P-5425, MIL-P-8184, and MIL-P-25690 required in the United States. In fact, MIL-P-8184 has been revised to recognize the improved performance of an enhanced crazed-resistant acrylic material.

Interior components in aerospace applications have seen an uptick in plastics use as well, specifically Kydex, an acrylic-polyvinyl chloride plastic which meets the demanding safety and non-flammability requirements of aircraft interior applications. Kydex is used for seat parts, bulkheads, monitor shrouds, window shades and tray tables. Kydex® 6185 meets FAR 25.853(a) for use in aircraft interior parts including overhead bins, components for navigational and propulsion functions, and structural elements.

Interior components in aerospace applications have seen an uptick in plastics use as well, specifically Kydex, an acrylic-polyvinyl chloride plastic which meets the demanding safety and non-flammability requirements of aircraft interior applications. Kydex is used for seat parts, bulkheads, monitor shrouds, window shades and tray tables. Kydex® 6185 meets FAR 25.853(a) for use in aircraft interior parts including overhead bins, components for navigational and propulsion functions, and structural elements.

As demand for high-performance aerospace plastics increase, the cost to create these materials decreases, and more applications are found or created through novel additives and new grades. The future of the aerospace industry is one filled with high-performance plastics playing a role in nearly every part of the operation, from engines to structural parts, piloting components to interior panels; all in the name of safety, reliability, cost-effectiveness, and an ability to operate in the most extreme conditions and go where no plastic, or man, has gone before. With experiments underway to find new uses for these materials, Mars may prove the next frontier in which plastics show their ability to bring aerospace ambitions to fruition.

Whether for government space programs, military operations, or aircraft, the choice of plastics over metals in aerospace comes down to a plastic’s ability to outperform their metal counterparts. As a true disruptor technology, plastics have shown they are not only on par with metals used in aerospace but also produce safer parts that hold up under more severe conditions, saving companies and governments money over the life of the components through fuel savings and part life.