The food processing industry looks to Plastic Machining Company as a reliable source for wear parts and plastic sheet, rod, tube, and profile suitable for food processing. On the heels of ProFood Tech Expo 2021’s cancellation, Plastic Machining Company aims to highlight three areas where plastics drive solutions for food processing industries.

Plastic Machining Company has long been a leader in wear part solutions for food processing machinery and continues to offer solutions for applications requiring food grade and FDA compliant plastics. From ultra-detectable blue acetal and other high-performance plastics to machined parts, Plastic Machining Company supplies the latest metal detectable and food-grade performance solutions for food processing technology.

TECAFORM® AH UD Blue acetal is an ultra-detectable food-grade plastic designed for use in food contact applications. Unlike other detectable plastics that only one or two methods may detect, all three standard detection processes see TECAFORM®: x-ray, optical scanning, and metal detection. TECAFORM® is ideal for food and beverage processing components, and conveyor belt technology components where detecting unwanted particulates is critical. In the food processing industry, materials that facilitate easier maintenance of plants or factories are always welcome. Wall cladding systems like the interlocking Duraclad™ and the antimicrobial but non-toxic Palclad Pro™ have high chemical resistance and are designed to withstand frequent sanitary maintenance over a prolonged period. With excellent structural strength, rigidity, and fire resistance, these PVC wall panel systems will hold up to food processing and production rigors.

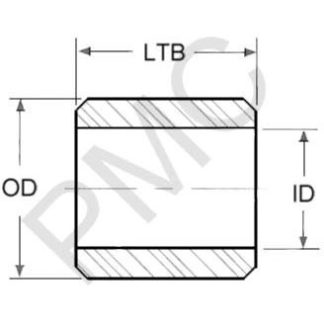

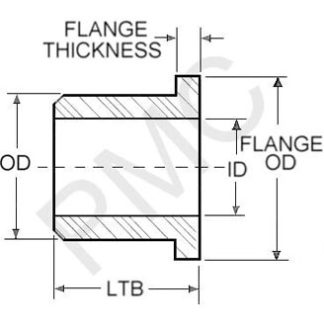

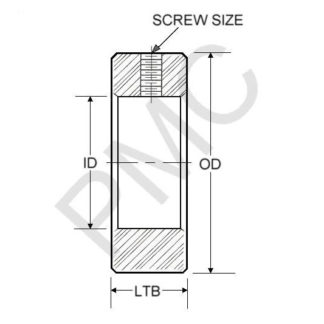

UHMW is an incredibly versatile material used in many industries, and food processing is no exception. Parts machined from UHMW can be used in nearly every aspect of the food production cycle. From rollers and guides in knife sharpening systems to wear strips for shellfish butchering, UHMW’s applications in the food processing industry are nearly endless. Plastic Machining Company has the experience and expertise to machine OEM and custom parts for power transmission in food processing applications.

Plastic Machining Company (PMC) provides industry-leading plastic machining, semi-finished sheet, and rod, custom-designed and OEM parts, as well as plastic replacements for metal power transmission components. PMC plastic sheet, rod, and parts are crafted from high-performance materials from Quadrant, Cast Nylons, Ensinger, Poly-Hi Solidur, and other resin converters, manufactured with precision state-of-the-art CNC routers, mills, and lathes. PMC parts scale from over twenty feet long and ten inches thick to parts that can rest on the tip of a finger. PMC can produce most custom parts within fifteen working days. Contact a PMC representative for specifics. Call 877-762-5449 or visit www.plasticmachiningcompany.com.