Plastic Machining Company offers solutions for flooring, roofing, walls, glazing, and doors – as well as custom-machined, OEM, and reverse machined parts.

PORTLAND, OREGON, UNITED STATES, March 24, 2021 — The building and construction industry is the nation’s second-largest consumer of plastics, next to packaging. In construction, plastics are building a reputation for utility, durability, aesthetics, easy handling, and high-performance. Plastic Machining Company offers a range of material solutions for flooring, roofing, walls, glazing, and doors – as well as custom-machined components, OEM parts, reverse machined power transmission parts, and other items custom-tailored to customers’ project specifications.

PORTLAND, OREGON, UNITED STATES, March 24, 2021 — The building and construction industry is the nation’s second-largest consumer of plastics, next to packaging. In construction, plastics are building a reputation for utility, durability, aesthetics, easy handling, and high-performance. Plastic Machining Company offers a range of material solutions for flooring, roofing, walls, glazing, and doors – as well as custom-machined components, OEM parts, reverse machined power transmission parts, and other items custom-tailored to customers’ project specifications.

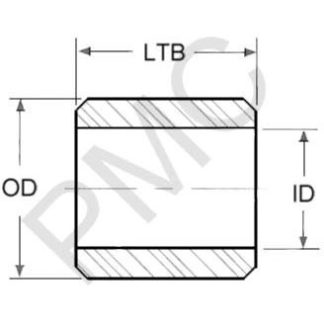

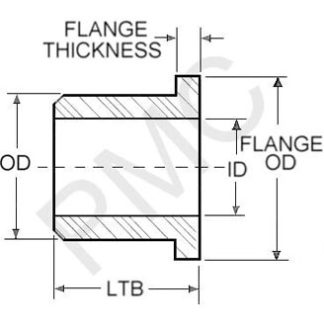

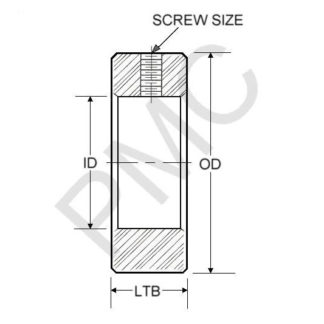

For heavy equipment and machinery, PMC offers application-specific parts including guides, belt scrapers, chain wear plates, skirt boards, belt rollers, scrapers and wipers, liners and plates, idlers and pulleys, loaders, conveyor parts, bucket liners, impact pads, beds & bumpers, sprockets, agitators, shoes and tracks, and other tools.

Construction and heavy equipment industries benefit from modern-day plastic materials and composites, which have become as strong if not stronger than many metals commonly used in the industry. More prevalent in the construction industry than ever before, plastics help to maximize energy efficiency, durability, performance, and part life. Plastic hardware is also frequently corrosion resistant, allowing it to survive outside in inclement weather indefinitely, a crucial consideration in construction.

Plastic Machining Company most commonly utilizes acetal, Delrin®, Nylon, and UHMW plastics. Acetal and Delrin® perform well in wet or moist environments and are desirable for their high impact strength and ease of machining. FDA and USDA-compliant grades make the materials more versatile in their applications. Nylon, a stiff mechanical and engineering thermoplastic with outstanding toughness, is lightweight, quiet, and decreases wear on mating parts when compared with stainless steel and other metals. Nylon is ideally suited for many bearing and wear applications in construction industry applications, and also comes in FDA-compliant grades. UHMW is a robust and low friction plastic with high chemical resistance, ideal for reducing friction, wear, energy consumption, and noise levels in countless heavy equipment applications.

From hospitals to schools, the construction of new homes to the retrofit and renovation of commercial buildings, architects and designers rely on plastics to increase efficiency, reduce energy and maintenance costs, and improve aesthetics and safety for years to come.

Plastic Machining Company (PMC) provides industry-leading plastic machining, semi-finished sheet, and rod, custom-designed and OEM parts, as well as plastic replacements for metal power transmission components. PMC plastic sheet, rod, and parts are crafted from high-performance materials from Quadrant, Cast Nylons, Ensinger, Poly-Hi Solidur, and other resin converters, manufactured with precision state-of-the-art CNC routers, mills, and lathes. PMC parts scale from over twenty feet long and ten inches thick to parts that can rest on the tip of a finger. PMC can produce most custom parts within fifteen working days. Contact a PMC representative for specifics. Call 877-762-5449 or visit www.plasticmachiningcompany.com.