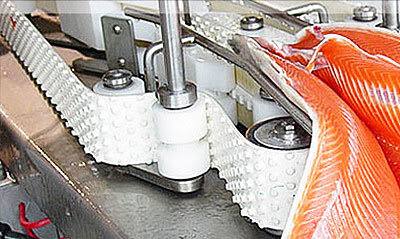

PMC is a leader in wear part applications providing the seafood industry materials that do not rust, do not require lubrication and have high wear resistance and a low specific gravity.

From sea salts that corrode, to wash down chemicals in the processing centers, PMC’s acetal, UHMW and other high-performance plastic parts for the seafood processing industry reduce costs with longer life, less lubrication and less wear & tear on mating components.

As there is generally no change in the design, between plastic and metal, of power transmission parts, most metal power transmission parts in seafood processing equipment can be directly swapped for a plastic counterpart, generally nylon or UHMW.

As there is generally no change in the design, between plastic and metal, of power transmission parts, most metal power transmission parts in seafood processing equipment can be directly swapped for a plastic counterpart, generally nylon or UHMW.

The seafood processing industry requires additional consideration for parts that may be exposed to moisture, sea salts (salt water), wash-down chemicals, and other heavy water contaminants. Customers have used PMC replacement parts in a variety of OEM fish and seafood processing equipment.

We have a wide selection of replacement parts including acetal, nylon and UHMW Bearings & Inserts, Bushings & Washers, Collars, Gears & Gear Racks, Chain Guides, Guide Rails, Outrigger Pads, Pulleys, Roller Chains, Sprockets, Tracks, and Wear Strips & Parts. Contact us today for your custom solution.

Features

- Corrosion resistant

- Self-lubricating

- Cost-effective

- FDA, USDA Compliant

- U.S. Standard and Metric sizes

Benefits for Seafood Processing Applications

- Reduced downtime

- Lower maintenance time

- Longer part life

- Reduced cost over stainless

- Direct replacement of metal products

- Huge inventory on hand in Portland, Oregon facility

Products

- Power Transmission components and custom manufacturing.

- Power Transmission parts for BAADER®, Stolle®, and other OEM equipment manufacturers

- Sprockets & hubs

- Gears & rack

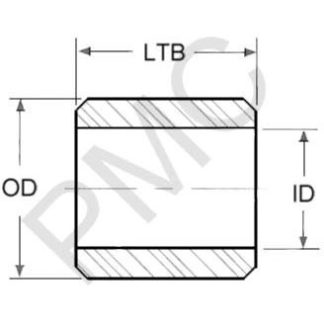

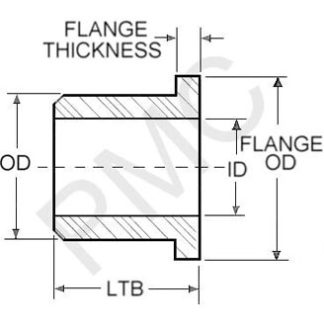

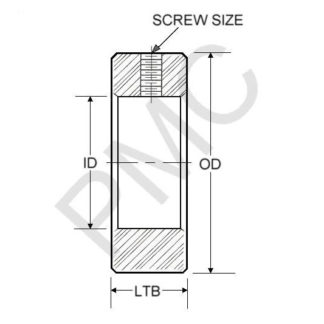

- Bearings & bushings

- Pulleys & sheaves

- Wear Strips & guides

- Polymer chains in three different plastics